iEcho Industrial Flatbed Cutting Systems | Digital Finishing & Automation

iEcho flatbed cutting solutions optimize digital post-printing workflows for the signage, packaging, and textile industries. These advanced CNC cutting systems revolutionize finishing with Computer Numerical Control (CNC) technology, delivering micron-level accuracy and accommodating an exceptionally wide range of media including foam board, corrugated board, textiles, rigid plastics, leather, gaskets, and composite materials for industrial applications and high-volume production.

iEcho Cutting Technology

Advanced industrial automation drastically reduces manual labor, eliminates hand-cutting inefficiencies, and significantly increases production throughput.

With precision down to 0.1mm and material compatibility up to 50mm thickness, iEcho systems provide a powerful, future-proof finishing technology solution for complex production workflows.

Industrial Finishing Innovation

Drastically reduces manual labor and eliminates hand-cutting inefficiencies. Achieve higher capacity and meet tight deadlines while reallocating staff to value-added activities.

Integrates with Adobe Illustrator, CorelDRAW, and nesting apps. Digital transfer maintains reproduction fidelity with precision down to 0.1mm.

Automatically optimizes design placement, achieving material utilization up to 95%. Minimizes scrap and maximizes ROI across premium substrates.

Superior precision via servo motors and optical recognition. Modular heads for oscillating, creasing, and kiss-cutting ensure professional-grade output.

Handles delicate fabrics to rigid foam boards, acrylics, corrugated cardboard, and industrial composites up to 50mm thickness.

Scalable solutions from compact benchtop to large-format industrial systems with cutting areas exceeding 3.2m x 2.5m.

Tooling system allows easy upgrades. Ensures a perfect balance of cutting area, speed, and precision for long-term growth.

Ensures absolute uniformity across all cuts with clean edges and accurate dimensions. Ideal for demanding signage and packaging.

Learn More About iEcho Technology

iEcho systems combine advanced CNC technology with industrial automation. They deliver 0.1mm precision, handle materials up to 50mm thick, and integrate with CAD/CAM workflows. Intelligent nesting software achieves up to 95% material utilization, significantly reducing waste.

Systems handle foam board, corrugated cardboard, rigid plastics (acrylic, PVC), textiles, leather, gaskets, magnetic sheets, and industrial composites. Modular heads allow oscillating, creasing, and kiss-cutting across multiple industries.

Advanced algorithms arrange cuts to achieve up to 95% material efficiency. This dramatically reduces scrap and lowers costs, which is critical when working with premium substrates like textiles and rigid acrylics.

Applications Gallery

Popular Use Cases

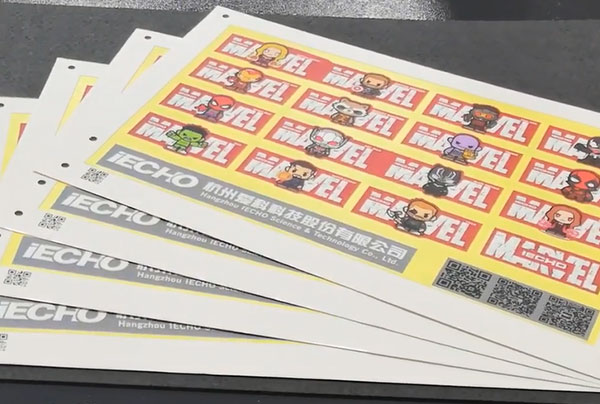

Excel in producing POP displays, exhibition graphics, and retail fixtures. Precision cutting of rigid substrates enables efficient fabrication of dimensional signage and trade show displays.

Perfect for short-run custom boxes and product prototypes. Multi-tool systems handle creasing and through-cutting for complex packaging designs with maximum efficiency.

Process textiles, leather, and composites for apparel, upholstery, and automotive industries. Enables efficient pattern cutting and gasket manufacturing in commercial environments.

Technology & Resource Videos

Additional Resources

Access detailed specs including cutting areas, material thickness (up to 50mm), precision (0.1mm), and tool configurations to select the optimal system.

Comprehensive training on software integration with Adobe Illustrator and CorelDRAW. Learn nesting strategies and automation techniques to maximize throughput.

Review case studies on material waste reduction (95% utilization) and labor cost savings through automation in signage, packaging, and textile manufacturing.

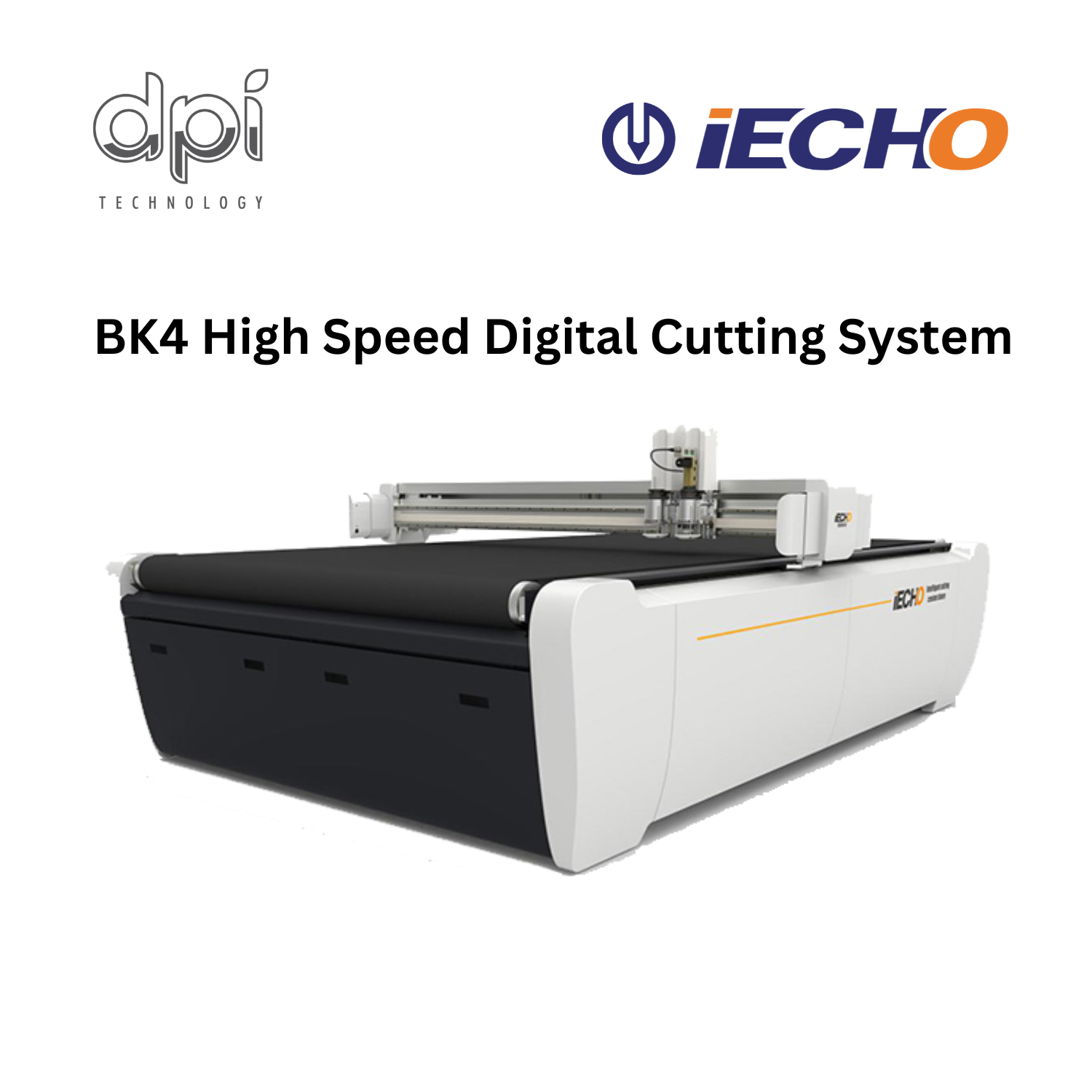

Available iEcho Flatbed Systems

Ready to Automate Your Digital Finishing?

Contact our industrial cutting experts to tailor an iEcho solution (flatbed or roll-feed) for your specific materials and production requirements.

Request an iEcho Quote Now