Roland TrueVIS AP-640 Resin Printer

Share

Features Overview

Build and expand your sign and graphics business with a wide range of applications, low running-costs, and the quick drying benefits of Roland DG's first large format resin/latex printer.

Until now, resin/latex printing was associated with flat, uninspiring color. Enter the TrueVIS AP-640 that’s redefining resin printing with high color saturation on a wide range of materials from uncoated PVC to non-PVC media. It features new TrueVIS resin ink and advanced machine features to optimize color reproduction on vinyl, paper, film, and specially formulated fabrics — expanding your graphics to include flags, roll-up screens, textiles, wallpapers, and so much more.

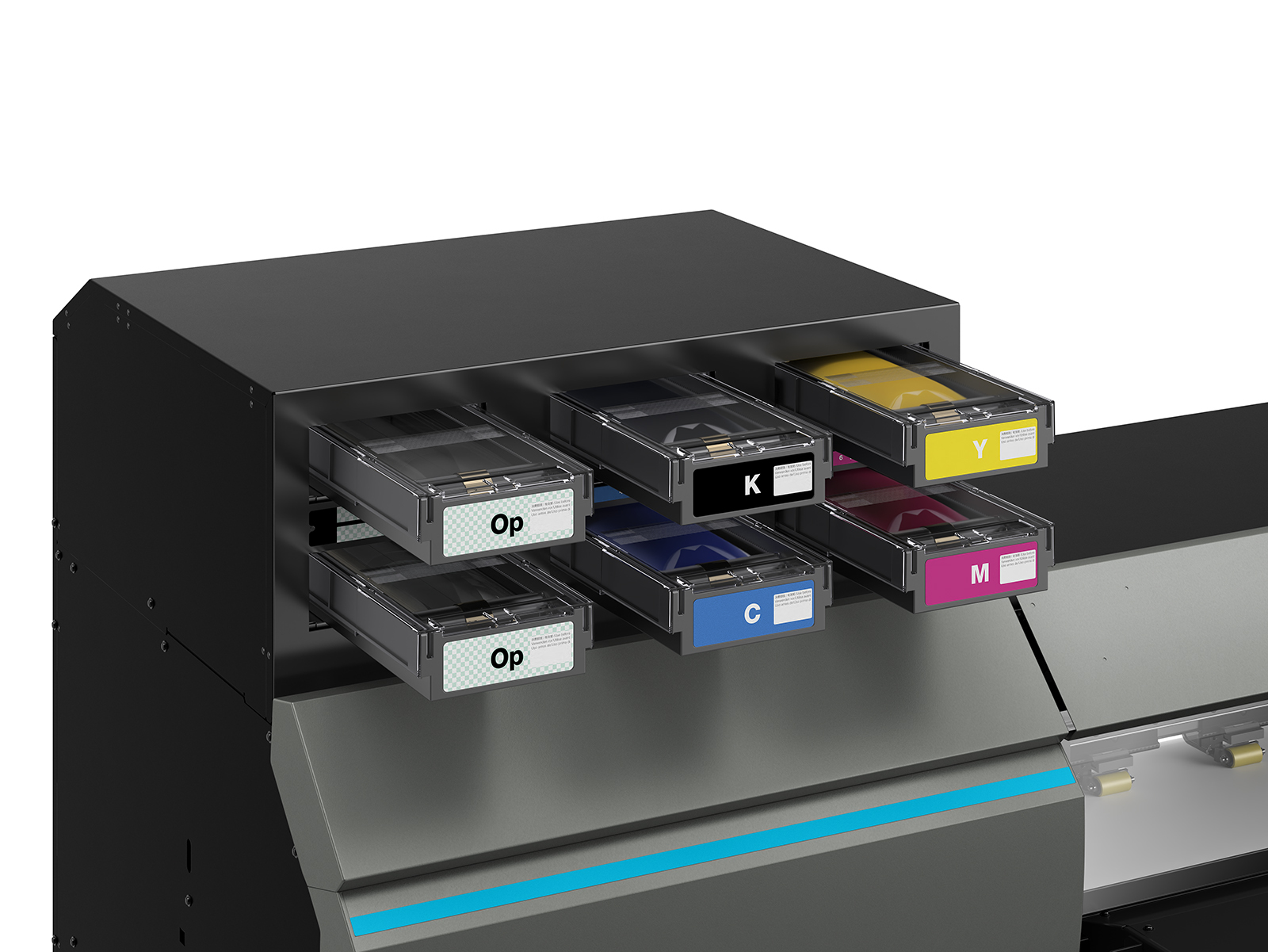

TrueVIS Resin Ink: The highly concentrated color pigmentation of TrueVIS Resin Ink enables heavier color saturation than conventional resin inks and printers for optimum graphic impact on paper, fabric, canvas, wallpaper, non-PVC materials, and other media.

Safety Comes Standard: With very low VOC emissions, Roland DG resin inks are ideal for interior applications where safety and compliance are the highest priority.

True Rich Color: The True Rich Color preset takes full advantage of the high color saturation of new TrueVIS Ink to maximize print vibrancy and ensure neutral greys, smooth gradations, and natural skin tones.

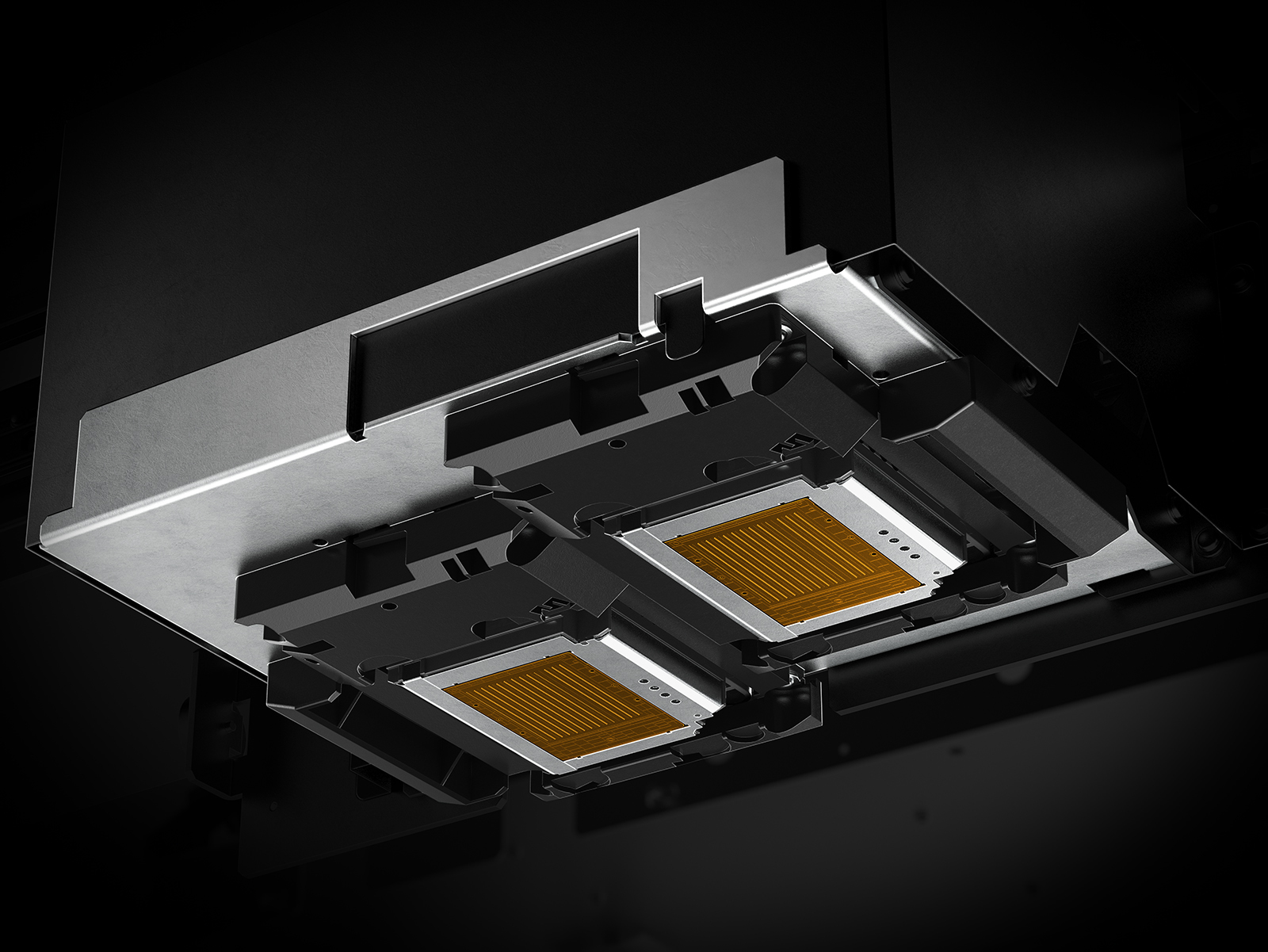

Variable Dot Printing: TrueVIS large format resin/latex printers benefit from hundreds of dedicated, media-specific printing profiles that control optimal ink volume and drying temperature. An optimizer prepares the media surface facilitating the formation of precise dots while variable dot control technology fires three types of ink droplets to create unparalleled image quality, producing natural beauty and vividness never before seen in a resin ink printer.

Dual Staggered Printheads for Resin Inks: Printheads are arranged in a dual, staggered formation with an optimizer printhead that preps the media surface for the CMYK printhead. This enables ink droplets to form a finer dot, resulting in more precise color and images.

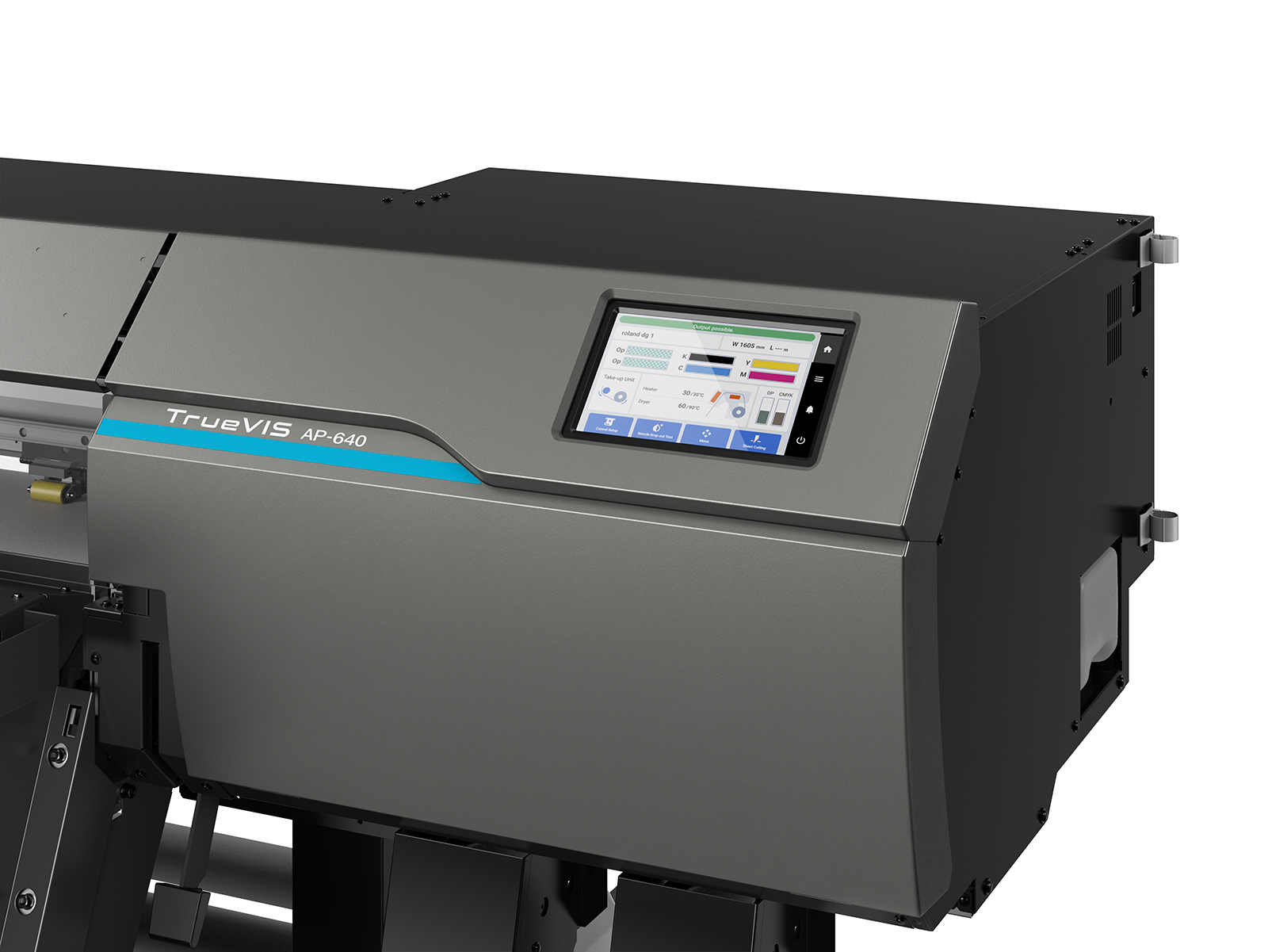

Automatic Gap Adjustment: Media gap and feed compensation can now be adjusted automatically with a single button. The AP uses optical registration technology to ensure print accuracy and avoid variations in output.

Included Take-Up Unit: An adjustable take-up provides print stability for a wide variety of popular media. It also allows easy installation of a loading platform for clean, efficient media collection.

Specification

| Printing method | Piezo ink-jet method | |

| Media | Width | 10.2 to 64 in. (259 to 1,625 mm) |

| Thickness | Max. 0.039 in. (1.0 mm) with liner | |

| Roll outer diameter | Max. 9.8 in. (250 mm) | |

| Roll weight | Max. 99 lb. (45 kg) | |

| Core diameter | 3 in. (76.2 mm) or 2 in. (50.8 mm) | |

| Printing width (*1) | Max. 63.5 in. (1,615 mm) | |

| Ink | Type | Resin ink 700 ml pouch |

| Colors | Four colors (cyan, magenta, yellow, and black) and optimizer | |

| Printing resolution (dots per inch) | Max. 1200 dpi | |

| Print heater set temperature: 77 to 113°F (25 to 45°C) | ||

| Dryer set temperature: 158 to 230°F (70 to 110°C) | ||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | |

| Power-saving function | Automatic sleep feature | |

| Rated Input | Printer: 200-240 Va.c. 50/60 Hz 3 A | |

| Dryer 1: 200-240 Va.c. 50/60 Hz 10 A | ||

| Dryer 2: 200-240 Va.c. 50/60 Hz 10 A | ||

| Power consumption | During operation | Approx. 4,000 W |

| Sleep mode | Approx. 65 W | |

| Acoustic noise level | During operation | 69 dB (A) or less |

| During standby | 53 dB (A) or less | |

| Dimensions (Width x Depth x Height) | 113.7 in. × 33 in. × 61.1 in. (2,886 mm × 836 mm × 1,550 mm) | |

| Weight (with stand) | 587 lb. (266 kg) | |

| Environment | During operation | Temperature: 68 to 86 °F (20 to 30 °C), |

| Humidity: 20 to 80 %RH (no condensation) | ||

| Recommended Environment | Temperature: 68 to 77 °F (20 to 25 °C), | |

| Humidity: 40 to 60 %RH (no condensation) | ||

| Not operating | Temperature: 41 to 104 °F (5 to 40 °C), | |

| Humidity: 20 to 80 %RH (no condensation) | ||

| Included items | Dedicated stand, power cords, dryers, media take-up unit, media holders, separating knife, replacement blade, cleaning liquid bottle for maintenance, drain bottle, User's Manual, software (VersaWorks, Roland DG Connect), etc. |